In the years that he has owned Dixie Trolling Motors (985-809-0685) in Mandeville, Louisiana, Todd Schultz has probably seen it all, not just with trolling motors he sells and services, but with Power-Poles and marine electronics as well.

But trolling motors were my interest, so I bombed him with questions.

Here’s what Schultz had to say.

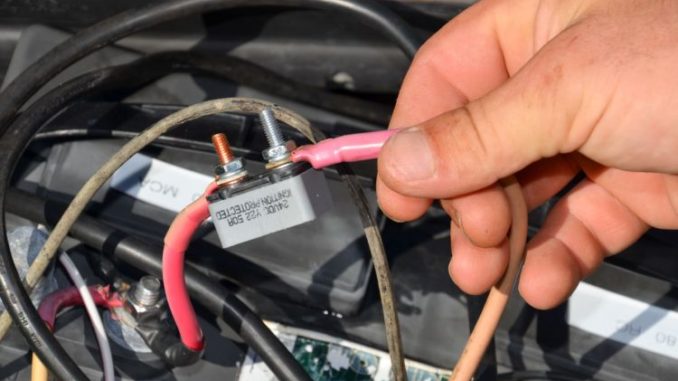

“For the majority of calls I get that say, ‘my trolling motor isn’t working,’ it’s the boat, not the trolling motor. The number one issue is a male-female plug issue. Corrosion builds up; corrosion causes resistance; resistance causes heat; heat causes fire.

“I urge people to apply dielectric grease to male-female connectors often. You can hardwire the trolling motor to the boat, but I don’t recommend it.

“In an emergency, you can’t disconnect the trolling motor from the system. Having connectors also makes service easier. You can just bring in the trolling motor rather than the whole boat.”

Resettable breakers that have tripped can also be a problem. But the solution is not to wire a trolling motor without one.

“The owner’s manual for the trolling motor will list the appropriate size breaker to use. A 50-amp breaker on a small trolling motor will allow the motor to fry before it trips. A 30-amp breaker installed in a heavy bay boat will cause the breaker to trip too often under heavy use.”

Surprisingly, Schultz said that dead batteries are often the problem with trolling motor malfunction.

“There is a difference between a battery maintainer built especially for trolling motors and an automotive charger. Trolling motor maintainers are trickle chargers. They will not recharge a deeply discharged battery.

“People will let their batteries go dead over the winter, then put the maintainer, which is labeled as ‘charger,’ on them. Then they take the boat out and the trolling motor doesn’t work.

“You would be surprised how often the problem is dead batteries. The only way to really tell if a battery is bad is with a multimeter, and ninety percent of people don’t how to use one.

“Three difference sizes of batteries are sold that can be used on trolling motors: Group 24, Group 27, and Group 31. The difference is in the size of the battery and the number of amp hours — reserve minutes; how much time you can get out of a battery. Get the biggest one that you can get in the boat.”

While Schultz was quick to admit that he isn’t a battery expert, batteries are obviously important for trolling motors. Three kinds of batteries suitable for trolling motors exist now, he said: lead acid, AGM (absorbent glass mat), and gel-cell.

The latter two have some advantages for trolling motor use, including the fact that they are “maintenance-free,” but they cost substantially more, starting at $200 each and going up. Lead-acid batteries start at $120.

“Most people want the cheapest they can get,” he said frankly. “So 95 percent of what I install are series 27 lead-acid batteries.”

Why not series 31? “They are substantially larger and often will not fit in the space available in the boat.

“Battery choice is one thing, but the worst thing that you can do to any battery is not check its fluid level and charge it when it is low.

“Thirty percent of the time, I find that batteries are the problem when a trolling motor doesn’t work!”