Sixth-grader Seth Kile has the hunting bug, and he came by it naturally.

The lights on your trailer are your boat’s first line of defense against collisions. Running lights show other drivers that you have a boat behind you when towing in the dark. Brake lights and turn signals can help keep tail-gating drivers from turning your stainless steel prop into a hood ornament, night or day. That is, of course, if your trailer lights work.Most boaters are familiar with the problems common to incandescent lights. Hot bulbs pop when immersed in water because “waterproof” really means “water resistant,” and they can’t stand the sudden cooling during submersion in water.

Eventually, we learn to unplug our trailer lights before launching. Seasons of dunking our lights slowly cause the bulb sockets in most housings to corrode, and replacing them usually means replacing the whole assembly. When you get to this point, you can prevent a lot of future problems by upgrading to LED lights.

Incandescent bulbs last about 3,000 hours (slightly more than four months of continuous operation) unless shock and vibration break their filaments or they die of thermal shock from being submerged while they’re hot.

LEDs are designed to last for about 100,000 hours of continuous operation (approximately 11 years). They are more resistant to damage because they have no fragile filaments to break, and some come sealed in polycarbonate housings that are almost bullet proof.

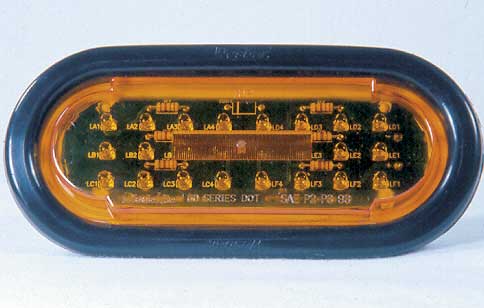

They have no bulb bases to corrode or sockets with spring-loaded contacts that can stick or lose tension. LEDs generate very little heat, and they aren’t killed by thermal shock. They require about 85 percent less energy than traditional bulbs, so they can reach full brilliance through less than perfect connections that might exist in an aging trailer lighting system.

LEDs reach full brightness about two tenths of a second faster than incandescent lamps when power is applied. So what? Well, it gives the driver behind you 20 extra feet of stopping distance when you are forced to slam on your brakes out on the highway. If he stops 10 feet behind your trailer, guess where he could have been if your trailer lights had conventional bulbs?

An LED light assembly’s least attractive feature is its price tag, but that is changing. A bulb-type tail light assembly might cost $18-20, while an LED model for the same application might run $30-37. A few years ago, the LED version could have cost four or five times as much as the incandescent model. Like all electronics, LED prices are coming down as their use increases. And, also as with other electronics, you are better off sticking with lights made by Wesbar, Optronics or another good manufacturer. All electronic devices are not created equal.

LEDs are now almost everywhere, from traffic signals to the lights on 18-wheelers, school buses, new cars and newer high-end boat trailers. If you see points of bright light organized in a pattern behind a light’s lens instead of a general glow, it’s an LED.

It’s easy to spot them, and that’s the point!